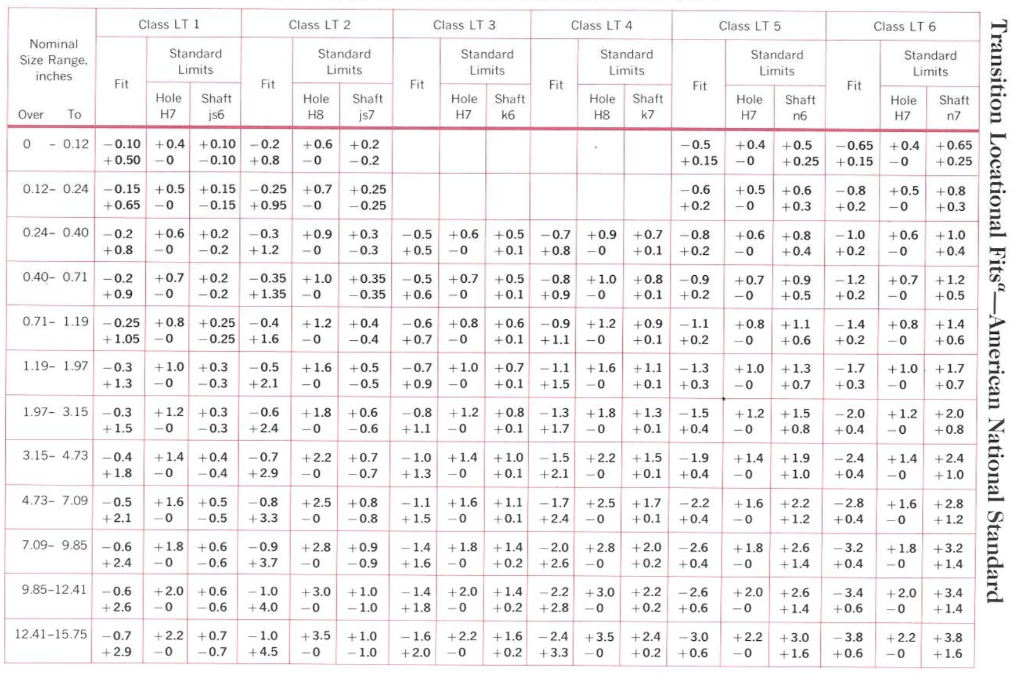

Running and Sliding Limits and Fits For Cylindrical Parts (ANSI B4.1-1967,R1987) All limits shown in chart below are in thousandths of an inches. Symbols H5,g5, etc. Are Shaft and Hole designations used in American-British-Canadian System (ABC). Limits for Shaft and Hole are applied algebraically to the Nominal (basic) size to obtain the. Table 6 - General Tolerances on Symmetry Table 7 - General Tolerances on Circular Run-Out Ranges of nominal lengths in mm Tolerance Class H K L up to 10 0.5 0.6 0.6 above 10 to 30 0.5 0.6 1.0 above 30 to 100 0.5 0.8 1.5 above 100 to 300 0.5 1.0 2.0 Ranges of nominal lengths in mm Tolerance Class H. The tolerance symbols that we use are in line with ISO 492 and ISO 199 and are explained in the previously mentioned tolerance tables and in table 12. The symbols normally refer to dimensional tolerances, only Kia, Kea, Sd, SD, Sia and Sea refer to geometrical tolerances.

We strive to bring to market high-quality, value-packed products. And we’re so confident in our 27-inch 2K monitors that we include a zero-tolerance dead pixel policy — the best in the market. Whereas other monitors for gaming require a cluster of 5 or more dead pixels, we’ll honor a replacement if you just see one single dead pixel. If the 0.12-inch wide channel is machined to 0.11 inches (the low tolerance side for the part), this further compounds the issue. Taking all three of these worst-case values under consideration, it is clear that the set screw will be 0.015 inches too far in one direction and will therefore not fit in the channel.

Plain washers are made of ferrous or non-ferrous metal, plastic or other material as specified. The tolerances indicated in the tables are intended for metal washers only.

American National Standard Type A Plain Washers - Preferred Sizes ANSI/ASME B18.22.1-1965 (R1998)

a Nominal washer sizes are intended for use with comparable nominal screw or bolt sizes.

b the 0.734-inch, 1.156-inch, and 1.469-inch outside diameters avoid washers which could be used in coin operated devices.

All dimensions are in inches.

Designation 'N' (narrow) and the Standard Plate 'W' (wide), these sizes as well as all other sizes of Type A Plain Washers are generally specified by ID, OD, and Thickness dimensions.

Location Tolerances: Inside and outside diameters shall be concentric to within the specified inside diameter tolerance.

Tolerance Table In Inch Conversion

© Copyright 2000 - 2021, by Engineers Edge, LLC www.engineersedge.com

All rights reserved

Disclaimer | Feedback

Advertising | Contact | Privacy Policy

Tolerance Table In Inch Cm

Date/Time:

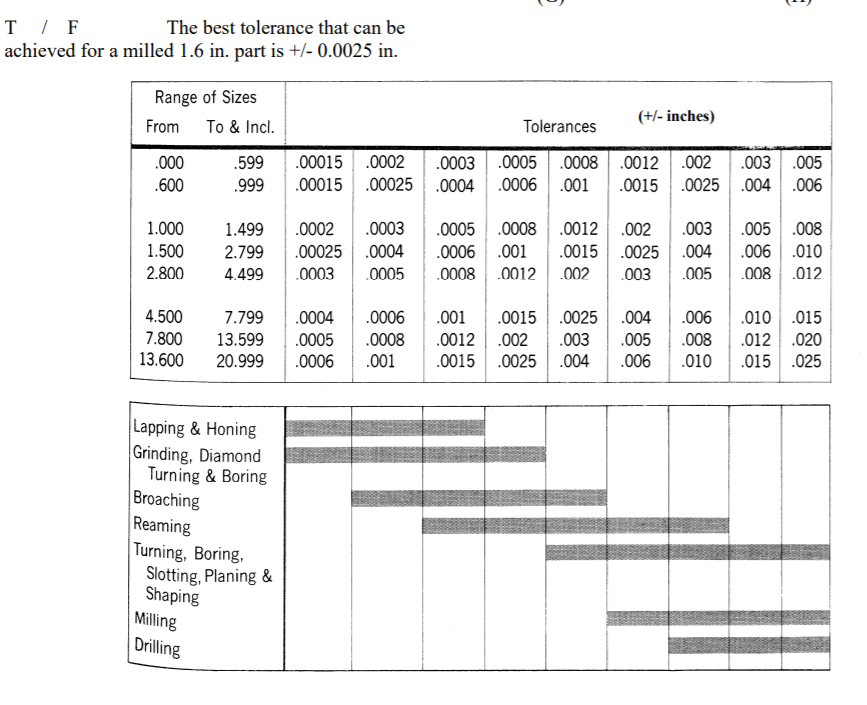

Tolerance Table In Inches

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||